With the release of Teledyne Tekmar’s AutoMate-Q40, I thought it was the perfect time to explain the QuEChERS Method that the instrument is based on. Below is a basic, but thorough, overview of what QuEChERS is and how it is performed manually step by step.

With the release of Teledyne Tekmar’s AutoMate-Q40, I thought it was the perfect time to explain the QuEChERS Method that the instrument is based on. Below is a basic, but thorough, overview of what QuEChERS is and how it is performed manually step by step.

What is QuEChERS?

QuEChERS is a Quick-Easy-Cheap-Effective-Rugged-Safe extraction method that has been developed for the determination of pesticide residues in agricultural commodities (fruits and vegetables). This extraction method was first developed by

S. Lehotay and M. Anastassiades at the USDA/ARS-ERRC in Wyndmoor/Pennsylvania.

Since the establishment of QuEChERS in 2003, the method has been continually refined, increasing the amount of known pesticides and applications for which the extraction can be used. The European Standard Method EN 15662.2008 and the AOAC 2007.01 methods were derived, in part, from refinements to the original unbuffered method.

QuEChERS is valued for its simplicity, low cost, low susceptibility to error, and ability to extract pesticides from various matrices. Additionally, it affords flexibility in the type of determinative analytical technique used. QuEChERS has gained acceptance globally as a reliable sample preparation method for pesticide residue analysis.

Standard QuEChERS Extraction Methods

QuEChERS consists of three standard extraction methods:- Original Unbuffered Method

- AOAC 2007.01 (Association of Analytical Communities)

- EN 15662.2008 (European Norm)

Who Uses QuEChERS?

- Commercial food testing laboratories

- Food producers, manufacturers

- Regulatory agencies (USDA, FDA, EFSA)

- Public and private auditing companies

QuEChERS Multi-Residue Method in Detail:

Below are detailed procedures for each step of the QuEChERS Method.Step 1: Homogenization and Sampling

|

|

|

|

Figure 1A: Homogenized sample |

Figure 1B: Weighing homogenized sample |

- The food sample (apple) is homogenized to increase the surface area available for extraction and to ensure a representative sample.

- The homogenizing process generates heat that can drive off the pesticides of interest and compromise the analysis. To minimize this, the sample is typically homogenized in a cryogenic/subambient condition.

- Typically 10-15 grams of the homogenized sample is transferred to a 50 mL centrifuge tube. For dry samples, especially those containing a water content <25% (e.g. flour, dried fruits, spices), the sample size may need to be reduced and water added prior to homogenization.

Step 2: Addition of Extraction Solvent

|

|

Figure 2: Addition of solvent |

- An extraction solvent is added to the centrifuge tube. It is recommended to use Acetonitrile because it can be easily separated from water. Because most food samples typically contain 80-95% water, separation of the sample from water is very important to this application. In general 10-15 mL of extraction solvent is added to the centrifuge tube.

- An Internal Standard solution can be added at this step to monitor extraction efficiencies and aid in the quantitation of the target analytes.

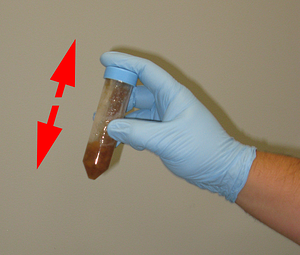

Step 3: Liquid Extraction

|

|

Figure 3: Shake for 1 minute |

- Once the solvent has been added to the tube, the tube is shaken vigorously for 1 minute.

Step 4: Buffering and Drying

|

|

|

|

Figure 4A: Extraction salts |

Figure 4B: Adding extraction salts |

The three accredited methods differ slightly on the amounts of salts and the type of buffering agents used. Typically the amount of Magnesium Sulphate that is added will exceed the saturation point, while the Sodium Chloride controls the polarity of the extraction solvent.

- Original Unbuffered Method: Magnesium Sulphate and Sodium Chloride

- AOAC 2007.01: Magnesium Sulphate and Sodium Acetate

- En 15662.2008: Magnesium Sulphate, Trisodium Citrate Dehydrate, and Disodium Hydrogen Sesquihydrate

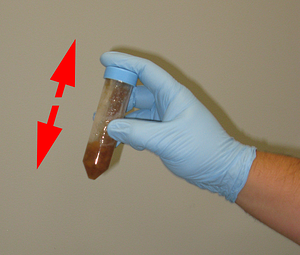

Step 5: Extraction

|

|

Figure 5: Shake for 1 minute |

- Once the extraction salts are added to the sample, the tube is shaken vigorously for 1 minute.

Step 6: Separation

|

|

|

|

Figure 6A: 50 ml Vials in centrifuge |

Figure 6B: Showing separation |

- The tube is centrifuged to separate the organic layer from the sample.

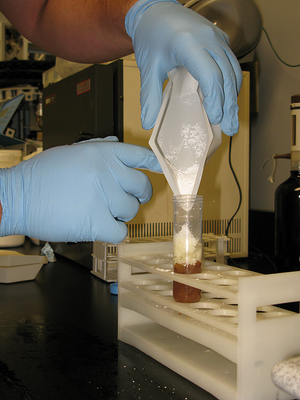

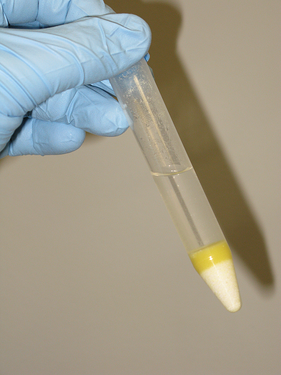

Step 7: Decanting and Dispersive SPE (dSPE) Clean-Up

|

|

|

Figure 7A: Decanting to the 15 ml vial |

Figure 7B: Shake for 30 seconds |

- An aliquot of the organic layer is decanted into a 15 mL centrifuge tube for clean-up by dSPE.

- The tube is shaken vigorously for 30 seconds.

- Primary Secondary Amine (PSA) and Magnesium Sulphate are the most common clean-up used for the dSPE. For high-fat samples, C18 will be introduced into the dSPE, but for high-chlorophyll samples and carotinoids, Graphitized Carbon Black (GCB) is introduced into the dSPE.

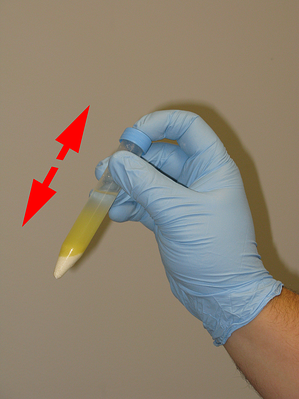

Step 8: Separation

|

|

|

|

Figure 8A: 15 ml vials in centrifuge |

Figure 8B: Showing separation |

- The 15 ml tube is centrifuged to separate the supernatant from the dSPE media.

Step 9: Decant the Supernatant

-resized-600.jpg?width=300&height=400&name=step_9_decant_off_to_sample_vial_(1)-resized-600.jpg) |

|

Figure 9: Decant to sample vial |

- The organic layer is decanted and placed into a 2 mL GC/LC sample vial.

- Depending on the detection scheme used and the desired reporting limits, a 2-10X concentration/dilution of the extract may be required to achieve the necessary sensitivity.

Step 10: Preservation & Analysis

- The supernatant can have 0.1% Acetic Acid, or 5% Formic Acid solution added as a preservative to ensure the stability of the pesticides (especially base-sensitive pesticides).

- It is also common to add “Analyte Protectants” such as Sorbetol, Gulonolactone or Ethylglycerol to the supernatant.

Automation of the QuEChERS Process

Teledyne Tekmar’s newest product innovation, the AutoMate-Q40, is specifically designed to automate the QuEChERS sample preparation workflow. Watch the video of the AutoMate-Q40 performing the QuEChERS extraction!The system is configured to conduct two of the most popular QuEChERS sample preparation methods:

- AOAC 2007.01 (Pesticide Residues in Food by Acetonitrile Extraction and Partitioning with Magnesium Sulfate)

- EN 15662.2008 (Foods of Plant Origin—Determination of Pesticide Residues Using GC-MS and/or LC-MS/MS Following Acetonitrile Extraction/Partitioning and Clean-up by Dispersive SPE-QuEChERS method).

Figure 10: The Teledyne Tekmar AutoMate-Q40

- Liquid dispensing/pipetting

- Vortex mixing

- Vial shaking

- Opening/closing sample vials

- Addition of solid reagents (ex. salts, buffers)

- Identifying liquid levels

- Decanting

- Centrifugation

- Matrix spiking

- dSPE clean-up

Blog Source:

Information in this blog was derived from the following sources. Information maybe be edited in content and length. For further information, please refer to the source document and/or website.- http://quechers.cvua-stuttgart.de/(accessed November 14, 2013)

-resized-600.jpg?width=300&height=225&name=step_6_50_ml_tube_centrifuge_(1)-resized-600.jpg)